-

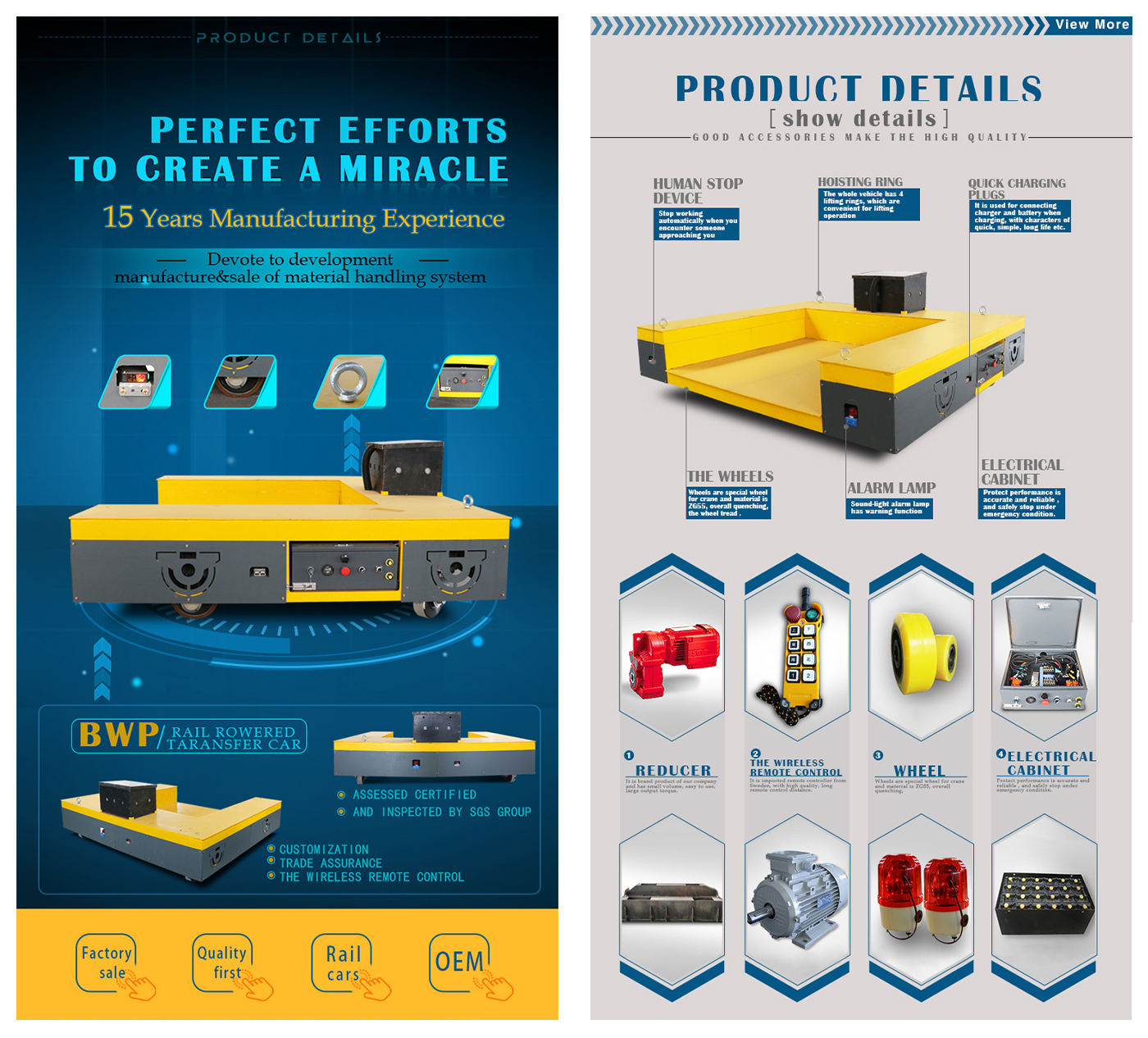

INDUSTRAIL TRAILER Ackermann Steering Trailer Double Directions Tow Trailer General Trailer Heavy Duty Trailer RAIL TRANSFER TROLLEY Battery Powered Transfer Trolley Cable Powered Transfer Trolley Rail Powered Transfer Trolley TRANSFER CART ON WHEELS AGV Differential steering Transfer Cart Hydraulic Steering Trackless Vehicle Omnidirectional Mobile Trackless Vehicle

-

English

English

中文简体

中文简体