-

17 06 2021

17 06 2021design example of six storey building

6. For all structural elements, M25 grade concrete will be used. However, higher M30 grade concrete is used for central columns up to plinth, in ground floor and in the first floor. 7. Sizes of all columns in upper floors are kept the same; however, for columns up to

Get Price -

17 06 2021

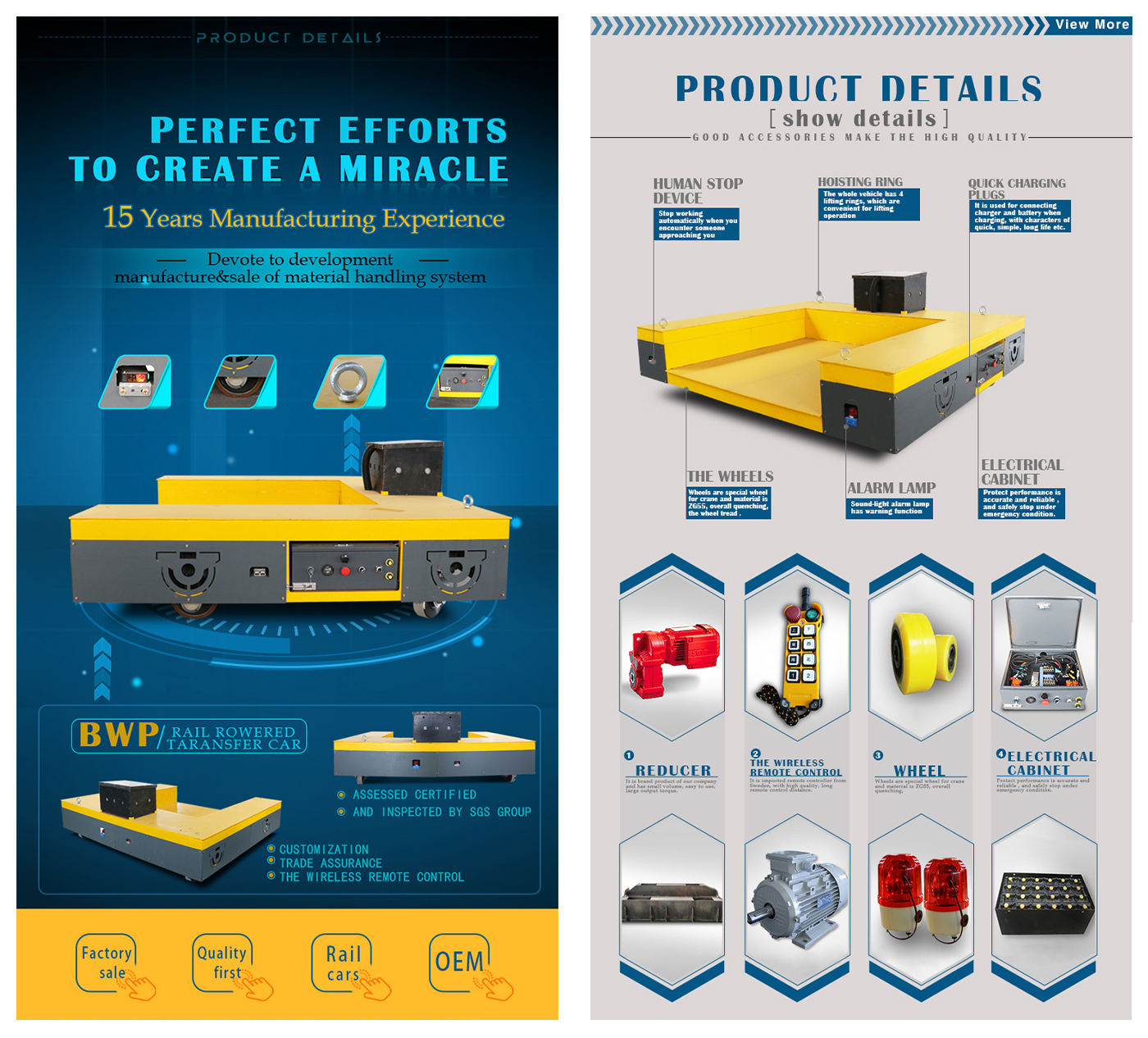

17 06 2021towed cable material handling rail cart for precast

Steel factory non-power transfer car flat bed towed material handling wagon. 1-150 ton cable reel power transfer railway material handling Get Price Precast Concrete Workshop Use 20t Heavy Duty Hard Rail

Get Price -

17 06 2021

17 06 2021Chapter 4 CONSTRUCTION METHOD FOR PRECAST SYSTEM

The diagrams below illustrated the sequence of installation for the precast beam-slab system: The Procedure • Setting Out 1. Surveyor to set cross reference. 2. Transfer grid and mark wall position on slab. 3. Mark 100mm offset line from rear building edge.

Get Price -

17 06 2021

17 06 2021Conceptual design and design examples for multi-storey buildings

Brussels, 18-20 February 2008 – Dissemination of information workshop 6 EUROCODES Background and Applications Steel beams supporting precast concrete slabs Span range5 to 10 m Structure depth 500 to 900 mm Integrated beams with deep decking

Get Price -

17 06 2021

17 06 2021Mixing and Transporting Concrete

concrete, a longer mixing time is required. 3.0 Transporting Concrete. Transporting the concrete mix is defined as the transferring of concretefrom the mixing plant to the construction site. Keep in mind that not allconcrete is mixed on the actual construction

Get Price -

17 06 2021

17 06 2021STRUCTURAL DESIGN OF HIGH-RISE BUILDINGS

In order to investigate how the different connections between the concrete cores affects the force distribution, an example case was used. The example case was modelled with wall elements with a dimension of three times four meters and a thicknessof0.55meters,seeFigure5.5. Thetotalheightofthewallsare12meters andthedistancebetweenthemarefourmeters. 51.

Get Price -

17 06 2021

17 06 2021Parking arage Collapse during Construction

• Footing: concrete pad used to transfer the weight from the columns to the ground. Columns are placed on a footing and secured in place by anchor bolts. • Anchor bolt: longer bolt imbedded in a footing to attach a column. • Shim (shim plate): used for

Get Price -

17 06 2021

17 06 2021Precast Concrete Building Solutions :Coreslab Structures - PCI

To be considered as restrained: c1+c2< 0.0025 for normal weight concrete c1+c2< 0.0010 for lightweight concrete Example: Determine maximum value of c1+c2for normal weight hollow core slabs with a clear span of 30 ft Solution: c1+c2= 0.0025(30 x 12) = 0.90 in. ℓ. Hollow-Core Slabs or Double Tees c1c2.

Get Price -

17 06 2021

17 06 2021Manual for the design of reinforced concrete building structures

Weight of concrete should be taken as 24 kN/m3. The initial design of prestressed concrete members should be carried out at the service- ability limit state using the following simplified load combinations (a) to (d): (a)dead load + imposed load.

Get Price -

17 06 2021

17 06 2021(PDF) Enterprise simulation of the precast concrete

In this first zone, the mixer works with the bullet car (m ix transfer car) in order to provide concrete to the casting zone. A set of transporters are working toge ther in the second zone to form

Get Price -

![<h3>Pile Foundation Design[1] - ITD</h3>](/wp-content/themes/Perfte/load/216/transfer carriage with ce.jpg) 17 06 2021

17 06 2021Pile Foundation Design[1] - ITD

1.4.9 Concrete pile Pre cast concrete Piles or Pre fabricated concrete piles: Usually of square (see fig 1-4 b), triangle, circle or octagonal section, they are produced in short length in one metre intervals between 3 and 13 meters. They are pre-caste so that (fig 1

Get Price -

17 06 2021

17 06 2021Precast Concrete: Advantages and Disadvantages

2/8/2018 · 1.3.3 PRECAST CONCRETE FLOOR SLAB. Precast concrete floor slab is the most fully standardized precast concrete elements. They are used for making floor and roof slabs. The principle advantages of precast floors are speed of construction, absence of scaffolding,Perfect variety of types,Perfect span capacity, & economy.

Get Price -

17 06 2021

17 06 2021CONSTRUCTION INSPECTOR’S CHECKLIST FOR PRECAST CONCRETE

PRECAST CONCRETE BOX CULVERTS While its use is not required, this checklist has been prepared to provide the field inspector a summary of easy-to-read step-by-step requirements relative to the proper construction of Precast Concrete Box Culverts

Get Price -

17 06 2021

17 06 2021PhD in Civil Engineering - Automated Quality Assessment

19/6/2017 · PhD in Civil Engineering - Automated Quality Assessment of Precast Concrete Elements Using 3D Laser Scan Data PhD in Civil Engineering - Automated Quality Assessment of Precast Concrete Elements Using 3D Laser Scan Data

Get Price -

17 06 2021

17 06 2021ENTERPRISE SIMULATION OF THE PRECAST CONCRETE

In this first zone, the mixer works with the bullet car (mix transfer car) in order to provide concrete to the casting zone. A set of transporters are working together in the second zone to form the final shape of the produced manhole in terms of mould and other

Get Price

-

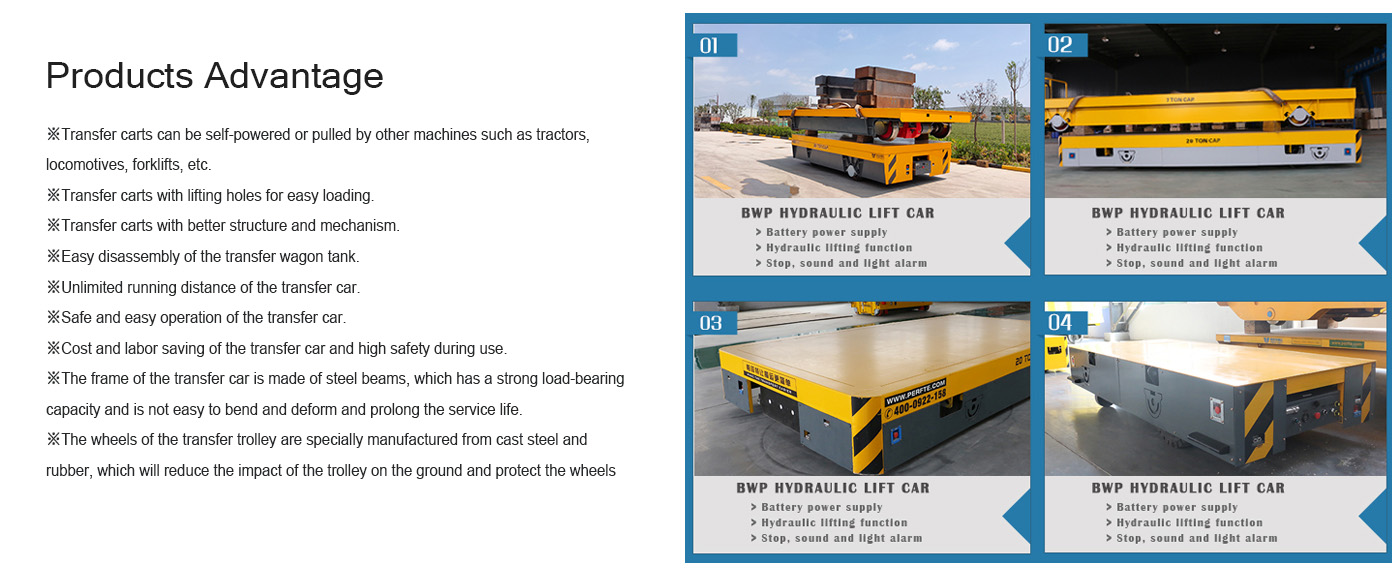

INDUSTRAIL TRAILER Ackermann Steering Trailer Double Directions Tow Trailer General Trailer Heavy Duty Trailer RAIL TRANSFER TROLLEY Battery Powered Transfer Trolley Cable Powered Transfer Trolley Rail Powered Transfer Trolley TRANSFER CART ON WHEELS AGV Differential steering Transfer Cart Hydraulic Steering Trackless Vehicle Omnidirectional Mobile Trackless Vehicle

-

English

English

中文简体

中文简体